Roll Crusher is simple structure, reliable, low cost, with a particle size of the nesting adjustable. The machine can be widely used for crushing and processing of cement, metallurgy, chemicals, electricity, coal and other industrial sectors, the soft material of brittle and ductile.

Roll crusher is applicable to sintered ore, coal, cement, silicates, glass, ceramics and other industries, suitable for the crushing of brittle materials, the following medium hardness is mainly used for ore crushing operations.

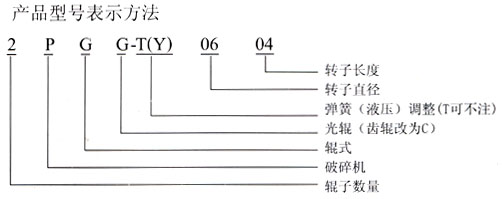

Roll crusher according to the number of rollers can be divided into single-roll crusher, double roll crusher, multi-roll crusher several types, according to the shape of the roller surface is divided into Smooth Roll Crusher, Roll Crusher, Roll mainly applies to secondary hardness of the ore crushing operations. Roll suitable for thick, brittle and soft materials in pieces.

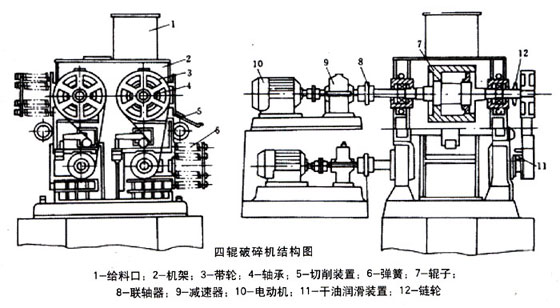

The roll crusher works: materials to be broken by falling into the feed port between the two rollers to rely on the role of the friction force into the rollers to squeeze the broken, the finished material from the lower fall. In case of strong or not broken things, the role of the roller rely on the hydraulic cylinder or spring automatically give way, so that the roller gap increases, perfect or not broken things down, to protect the machine from damage. Opposite rotation of the roller gap, to change the gap, you can control the maximum nesting granularity. The double roll crusher using a pair of opposite rotation of the circle roll, four roll crusher is the use of two pairs of opposite rotation of the circle roll crushing operations.

Features: double roll crusher V-belt or universal joint couplings for the transmission and regulation of the gap between the two rollers. The four-roll crusher gap between the V-belt drive and adjust the roller.

Double roll crusher main technical parameters:

|

類型 |

型號 |

輥子直徑/長度

mm |

最大進(jìn)料粒度

mm |

出料粒度

mm |

生產(chǎn)能力

t/h |

電動機功率

kw |

輥子轉(zhuǎn)速

rpm |

重量

kg |

|

雙輥破碎機 |

2PG3030 |

Φ300/300 |

20 |

0-15 |

1.5-5 |

2x2.2 |

60 |

543 |

|

2PG4025 |

Φ400/250 |

32 |

0-8 |

5-10 |

2x5.5 |

200 |

1300 |

|

2PG6040 |

Φ600/400 |

85 |

0-12 |

4-15 |

2x11 |

120 |

3500 |

|

2PG6090 |

Φ600/900 |

85 |

0-12 |

8-35 |

2x15 |

120 |

8300 |

|

2PG7550 |

Φ750/500 |

100 |

0-12 |

10-40 |

2x15 |

80 |

9200 |

|

2PG120100Y |

Φ1200/1000 |

40 |

2-12 |

15-90 |

2x45 |

75 |

46400 |

|

2PG120100T |

Φ1200/1000 |

40 |

2-12 |

15-90 |

2x45 |

75 |

45400 |

The main technical parameters of four-roll crusher

|

型號 |

轉(zhuǎn)子工作直徑/長度

(mm) |

輥子間隙

(mm) |

進(jìn)料粒度

≤mm |

產(chǎn)量

t/h |

電動機 |

外形尺寸 |

重量

t |

|

功率kw |

電壓v |

|

4PGG-750500 |

Φ750x500 |

0-12 |

85 |

20-60 |

11/24/30 |

380 |

2.76x3.59x2.65 |

19.2 |

|

4PGG-Y0907 |

Φ900x700 |

0-12 |

100 |

30-70 |

15/24/30 |

9.0x4.2x3.2 |

27.2 |

|

4PGG-T0907 |

Φ900x700 |

0-12 |

100 |

30-70 |

30/15/22 |

4.2x3.2x3.2 |

26 |

|

4PGG-Y1210 |

Φ1200x1000 |

0-12 |

100 |

40-80 |

40/55/75 |

9.61x5.6x4.24 |

67 |

Roll Crusher Main technical parameters:

|

型號 |

上/下齒輥直徑x長度

mm |

進(jìn)料粒度

mm |

出料粒度

mm |

破碎能力

t/h |

電動機功率

kw |

重量

kg |

外形尺寸

mm |

|

2PGC4550 |

450x500 |

< 200 |

< 12 |

15-30 |

18.5 |

4300 |

2492x2160x760 |

|

2PGC6075 |

600x750 |

< 200 |

< 12 |

20-50 |

30 |

6800 |

3265x2780x1360 |

|

2PGC60100 |

600x1000 |

< 200 |

< 12 |

30-70 |

45 |

8700 |

4820x2887x1360 |

|

2PGC9090 |

900x900 |

< 300 |

< 12 |

40-80 |

45 |

13200 |

3974x2827x1650 |

|

2PGC1012 |

1000x1200 |

< 300 |

< 12 |

60-120 |

55 |

13500 |

4820x2860x1450 |

|

4PGC40/38/60 |

400/380x600 |

< 300 |

< 12

< 25 |

30-60

50-80 |

18.5/22 |

7100 |

2355x1805x1450

上230r/min

下280r/min |

|

4PGC40/38/120 |

400/380x1200 |

< 300 |

< 12

< 25 |

50-90

80-150 |

75 |

9600 |

3650x1805x1450 |

|

4PGC76173 |

760x1730 |

< 300 |

< 12

< 25 |

180-300

250-400 |

3*75 |

17600 |

5770x1920x1860 |

|

4PGC80100 |

800x1000 |

< 300 |

< 12

< 25 |

60-100

90-125 |

75 |

16000 |

5270x1970x1920 |

|

4PGC11080(Y) |

1000/1100x800 |

< 300 |

< 8

< 13

< 25 |

100-140

130-180

170-260 |

55/75 |

21000 |

4614x1824x2340

(4614x3834x2340) |

|