Buried scraper conveyor Product Overview:

Buried scraper conveyor series products are widely used in metallurgy, building materials, electricity, chemicals, cement, ports, terminals, coal, mining, oil, food, feed, and other industries and sectors. Buried scraper conveyor is a giant in a closed-shaped section of the housing by means of a moving scraper chain to deliver continuous bulk material transport equipment; as in the transportation of materials, scraper chain among all buried in the material , so it called en masse conveyor. Simple structure, good sealing, easy installation and maintenance, process layout flexible; it is not only the level of transmission, but also inclined or vertical transport; either stand-alone use, but also more than one joint use; can do more to feed, but also more point of discharge.Because of the closed shell, and therefore transport large, toxic, explosive, can significantly improve workers' working conditions and environmental pollution prevention and control high-temperature materials. Buried scraper conveyor is a much metallurgy, mining, thermal power plants welcome conveying material system equipment. Buried scraper conveyor Product Abstract: Buried scraper conveyor is a rectangular cross-section in a closed shell by means of a moving scraper chain conveyor continuous bulk material transport equipment strong, because in the transportation process, scraper chain It is buried in the material being conveyed, and therefore called "buried scraper conveyor." Buried scraper conveyor in a horizontal conveyor, the material by scraper chain pressure and the material in the direction of movement of the weight of its own role in the internal friction between the material produced. This ensures the steady state friction material layer, and sufficient to overcome the external friction material in the machine tank movement generated, so that the material to form a continuous whole stream is conveyed. When vertical lifting, the material by scraper chain in the direction of movement of the pressure, resulting in a transverse direction of the side of the pressure in the material, the formation of the internal friction of the material.At the same time due to the constant feeding the lower horizontal section. The lower part of the upper material of the material have been produced tractive force. This force is sufficient to overcome the friction and goes outside the friction material in the machine slot and material movement generated by its own weight, the material forms a continuous stream and is integral promotion. Scraper conveyor simple mechanism, light weight, small size, strong sealing, installation and maintenance more convenient; it is not only the level of transmission, but also to tilt or vertical lift transport; can do more to feed, but also multi-point discharge conveyor more flexible process layout.Since the case is closed, which convey Gigalight, toxic, explosive, high temperature materials, to improve the operating conditions of the workers and to prevent environmental pollution and other aspects of the more prominent advantages.

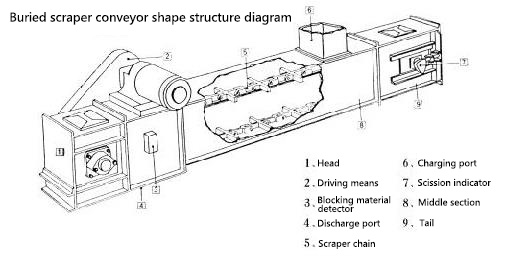

Scraper conveyor product structure diagram Buried:

Buried scraper conveyor products common models and schematic layout:

Buried scraper conveyor Product Features

1, buried scraper conveyor horizontal transport commonly used in particle and powder materials, also for delivery in the 150 ° tilt angle range;

2, buried scraper conveyor with high whole life, smooth operation, small structure size, low throughput, energy consumption, material breakage rate and other characteristics;

3, buried scraper conveyor reasonable structure, can be multi-point feeding, the moving speed of the blade in the lower drive gear, smooth running, low noise, single-point access to materials on the basis of, but also multi-point feed multi-point discharge, terms of delivery of toxic, explosive, high-temperature materials and ease of flying, improve workers operating conditions and reduce environmental pollution and other outstanding features.

Buried scraper conveyor product works:

In a closed cabinet scraper chain by moving friction coal and coal continuous output, buried scraper chain conveyor of the solid coal is connected to the drag chain scraper at run time in a closed trough conveying bulk material conveyor. This drag chain conveyors are embedded in the material and the blade, the blade is only part of the chute section, accounted for most of the material chute section. It horizontal, inclined or vertical transportation of materials.When the level of transmission, the use of the blade is flat strip, use embedded bulk of the chain and the blade of the cutting forces bulk layer is greater than the groove wall of the principles of bulk resistance, so that the bulk material with the scraper move forward together, than at this time to move the material layer height and width of the ratio within a certain range, the material flow is stable.

(1) buried scraper conveyor horizontal transport, the material by scraper chain pressure of its own weight and material direction of movement in the internal friction between the material produced. This ensures the steady state friction material layer, and sufficient to overcome the external friction material in the machine tank movement generated, so that the material to form a continuous whole stream is conveyed.

(2) buried scraper conveyor in the vertical lift, the material by scraper chain in the direction of movement of the pressure, resulting in a transverse direction of the side of the pressure in the material, the formation of the internal friction of the material. At the same time due to the constant feeding the lower horizontal section of the lower part of the upper material of the material have been produced tractive force. This force is sufficient to overcome the friction and goes outside the friction material in the machine slot and material movement generated by its own weight, the material forms a continuous stream and is integral promotion.

Buried scraper conveyor Technical parameters:

|

MS, GSS Horizontal scraper technical parameters Reference Table |

|

Model |

12 |

16 |

18 |

20 |

25 |

30 |

32 |

35 |

40 |

50 |

60 |

63 |

|

Machine groove width(mm) |

120 |

160 |

180 |

200 |

250 |

300 |

320 |

350 |

400 |

500 |

600 |

630 |

|

Scraper chain |

Pitch(mm) |

100 |

100 |

125 |

125 |

125 |

200 |

200 |

200 |

200 |

200 |

250 |

250 |

|

125 |

125 |

160 |

|

Line speed(m/s) |

0.133

-

0.183 |

0.133

-

0.166 |

0.167

-

0.192 |

0.183

-

0.2 |

0.183

-

0.245 |

0.266-0.3 |

0.275-0.35 |

|

Throughput(m3/h) |

6.912

-

9.504 |

15.36

-

19.87 |

19.44

-

22.35 |

13.76

-

25.92 |

33

-

44.1 |

71.82

-

81 |

76.61

-

86.4 |

100.5

-

113.4 |

126.4

-

142.65 |

172.36

-

194.65 |

213.84

-

272.16 |

249.48

-

317.52 |

|

Conveying distance(m) |

10-50 |

|

Motor(kw) |

2.2-22 |

|

MC, MZ, GSZ.GSL type buried scraper conveyor technical parameters Reference Table |

|

Model |

12 |

16 |

18 |

20 |

25 |

30 |

32 |

35 |

40 |

50 |

60 |

63 |

|

Machine groove width(mm) |

120 |

160 |

180 |

200 |

250 |

300 |

320 |

350 |

400 |

500 |

600 |

630 |

|

Scraper chain |

Pitch(mm) |

100 |

100 |

125 |

125 |

125 |

200 |

200 |

200 |

200 |

200 |

250 |

250 |

|

125 |

125 |

160 |

|

Line speed(m/s) |

0.1

-

0.183 |

0.133-0.183 |

0.283

-

0.25 |

0.21-0.26 |

0.26-0.306 |

0.25-0.35 |

|

Throughput(m3/h) |

3.89

-

5.17 |

9.22

-

12.67 |

10.37

-

14.25 |

12.48

-

17.16 |

33

-

36 |

36.29

-

44.39 |

38.7

-

47.92 |

56.7

-

69.4 |

64.8

-

79.3 |

90

-

110.16 |

118.8

-

166.32 |

124.74

-

174.64 |

|

Conveying distance(m) |

Vertical 20 horizontal 25 |

|

Motor(kw) |

2.2-22 |

Installation buried scraper conveyor:

Buried scraper conveyor installation needs to do the following:

1) Location:

First fix the position of the nose and tail, and then fix the centerline of the scraper conveyor.

2) the laying of an intermediate groove:

The conveyor centerline fixed for laying in the middle slot. Such as the use of non-metallic groove box, the middle groove paving bricks and cement panels, cast stone and then bonded liner. Cast stone lining when laying flat to note, as little seams, the longitudinal slit to stagger work will prevent ground slit trench.

Laying flat surface conveyor needs, as there are within conveyor plane excessive bending, it will inevitably lead to discontinuity two chains, accelerated wear between chain and groove wall cast stone, and even card chain. Each segment should be flat without overlapping tank level. Due to structural constraints tank itself, adjacent the central groove deflected in the vertical direction should not be too large. If the conveyor is not laying flat, transportation consumption will increase. Machine aisle product coal or debris should be swept away.

3) Install the nose and tail:

Nose and tail should leave some space, easy maintenance and repair. Sprocket centerline perpendicular to the centerline of the conveyor, and the level of assurance.

4) mounted scraper chain:

Scraper chain prior to installation, should be pre-connected, the blade is evenly distributed in the chain. If the two chains, to choose equal length, or press the pairing chain assembly factory. The chain may not have reverse phenomenon. Ring chain seam side up to prevent the chain and sprocket grip phenomenon occurs.

5) Check and empty running:

After the conveyor is installed, it should conduct a comprehensive inspection and start the conveyor. Air operation 2h, mainly the drive means and the blade is functioning properly. At the same time, so that abut the adjacent middle slots, again tight chain, adjust the chain length.

Scraper conveyor within the first two weeks of work, should pay special attention to the tightness of the chain. The method of inspection is: If the tail drive means, then jog the drive unit, when the shares of the tail sprocket chain more than two full relaxation of chain link, the need to dismantle the chain tight chain or minus ring, reducing link lengths. If only the head drive means you will need to reverse jog the motor, when the shares of the chain at the nose sprocket with more than two full relaxation of chain ring. Also we need to dismantle the chain tight chain or subtract rings.

Buried scraper conveyor is mainly divided into the following types: 1, the horizontal-type buried scraper conveyor 2, a vertical-type buried scraper conveyor 3, Z-type buried scraper conveyor

Note: Our factory can design and produce other types of buried scraper conveyor according to user requirements. |