BLQ chain slat conveyors Overview:

BLQ chain plate conveyor (referred to as chain plate machine), is in the B series medium plate feeder based on the improved design. Between chain plate machine redirection sprocket drive sprocket and around two chain with a hook and chain L-lose trough coupling, the drive will power drive sprocket, drive chain and transport trough running to reach the purpose of transporting materials.

Chain plate machine is a delivery device can also be used to transport other bulk, block granular, bulk materials, has been widely used in building materials, metallurgy material handling, mining waiting for industry.

Second, BLQ chain plate conveyor features:

Chain plate machine design is reasonable, good performance, low running resistance, less wearing parts, safe operation, easy maintenance, reliable operation and long service life. Chain plate machine can be horizontal or inclination <30 ° installation, Canted, with backstop ratchet mechanism.

Third, BLQ chain plate conveyor main structure:

Chain plate machine consists of a head frame, head cover, sprocket set, conveying equipment, central rack, rear rack, redirecting sprocket set, the next roller set, the roller and the driving device component group .

YTC gear driven by a motor unit, pin couplings, JZQ reducer, drive base composition. And installed two minutes left and right equipment, from the tail to see the transport direction, driving means mounted on the right side of the right, to the left of the left wear.

Sprocket assembly structure, made of cast steel sprocket ring and sprocket bolt coupling core portfolio, strong wear resistance, easy removal installation. The drive sprocket wheel using eye socket ring, chain operation to prevent sliding.

Precautions:

1, this device is mainly used for transporting wear strong, high temperature materials.

2, the power unit in the chain plate machine head, left and right equipment can vary.

3, delivery speed is 8 ~ 10m / min is appropriate, too low to affect delivery volume, large high noise and increased wear. And BLQⅡ800, BLQⅡ1000 suitable for conveying bulk density of less material.

4, this model Slat chain conveyors transport within the appropriate distance of 30 meters.

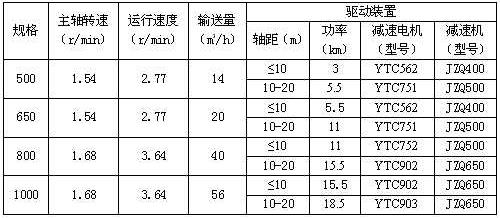

Third, BLQ chain plate conveyor technical parameters:

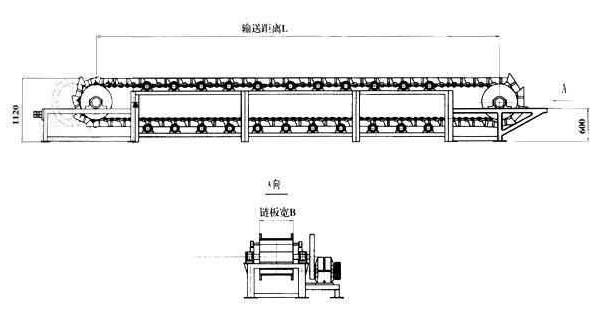

Fourth, BLQ chain plate conveyor structure diagram:

|