First, DTⅡ special type mine belt conveyor Overview:

DTⅡ belt conveyor is a universal type conveyor series products, widely used in metallurgy, mining, coal, ports, power plants, building materials, chemical industry, light industry, petroleum and other industries, used to transport bulk materials or items. As noted in transportation technology requirements, single delivery to be more than one or the other conveyors horizontal or inclined conveyor system can be transported in bulk density of 0.5 ~ 2.5t / m3 of material.

Second, DTⅡ Belt Conveyor Features:

1, DTⅡ type fixed belt conveyor suitable working environment temperature -25 ~ + 40 ℃. For special circumstances, such as to have heat, cold, waterproof, corrosion, explosion, fire and other conditions, should take appropriate protective measures separately.

2, DTⅡ type fixed belt conveyor according to part series design. Designers can according to different terrain, working conditions and combining the entire selection and design conveyor according to transportation process requirements.

3, this series of components to meet the requirements of the horizontal and inclined conveyor, can also be used with a convex arc, delivery form concave arc and a straight segment combinations. Allow delivery of materials depends on the bandwidth of the block, with speed, groove angle and inclination, depending on the frequency of bulk materials also occur.

Third, DTⅡ belt conveyor is arranged in the following a few basic forms:

1. The horizontal conveyor

2. Tilt Conveyor

3. With a convex arcuate shaped conveyor section

4. With concave arcuate shaped conveyor section

5. The band Concave and convex arcuate shaped conveyor section

Fourth, DTⅡ belt conveyor overall structure:

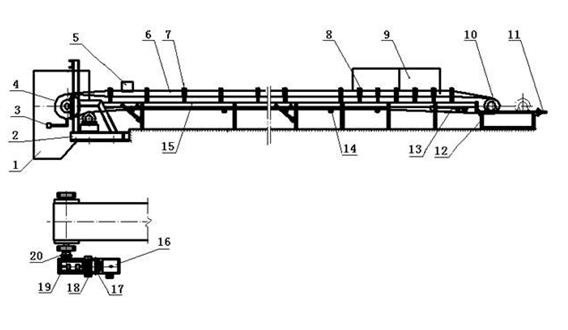

The main components as follows: conveyor belts, driving means (motor, gear, hydraulic couplings, brakes, couplings, backstop) or electric rollers, drive pulley, bend pulley, roller, tensioning device, sweeper , discharge, rack, funnel, guide trough, safety protection devices. (See figure below)

1, the head of the funnel, 2, rack, 3, head cleaning, 4, the drive roller, 5, security devices, 6, conveyor, 7, carrying rollers, 8, buffer roller 9, guide material slot, 10, bend pulley, 11, spiral tensioning device, 12, tailstock, 13, empty segment sweepers, 14, return idlers, 15, intermediate frame 16, a motor 17, hydraulic coupler, 18 , brakes, 19, reducer, 20, coupling

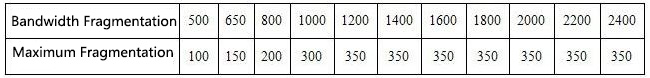

Various bandwidths applicable largest block of this series recommend selected according to Table 1. When transporting hard rock, post-bandwidth exceeding 1200mm, the largest block of generally should be limited to 350mm, and can not but increase with the bandwidth growth.

Table 1DTⅡ belt conveyor various bandwidths applicable Maximum fragmentation:

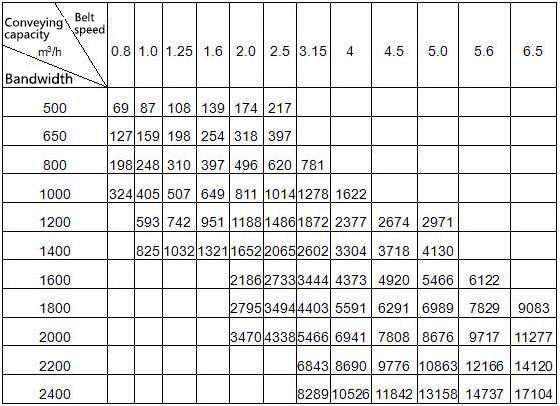

Table 2DTⅡ type belt conveyor main parameters:

Table relationships 3DTⅡ type belt conveyor drive type and drive power:

Transmission form |

Power Range (Kw) |

Remark |

Flexible coupling direct drive |

2.2~37 |

When power ≤200kw voltage 380V / 660V |

Y series electric plus hydraulic coupling |

45~315 |

Electric power cylinder direct drive |

2.2~55 |

When power ≥200kw voltage 660V |

Wound motor |

220~800 |

|