First, DJ-steep belt conveyor Overview:

DJ-steep belt conveyor structure is in flat-shaped rubber conveyor belt on both sides glued freely retractable rubber waveform vertical "skirt", between the skirt and stick with a certain strength and elasticity of the crossbeam composition box shaped bucket, so that the material is continuously transported in the bucket. It can be widely used in coal, food, building materials, chemicals, utilities and metallurgical sectors, the ambient temperature is within the range of -15 ℃ ~ + 40 ℃, transporting bulk specific gravity of various bulk materials 0.5-2.5t / m3 of. There are special requirements for the delivery of materials, such as high temperature, with materials acid, alkaline, oils or organic solvents and other ingredients, it requires the use of special sidewall conveyor belt, transportation within the angle 0 ° ~ 90 ° range.

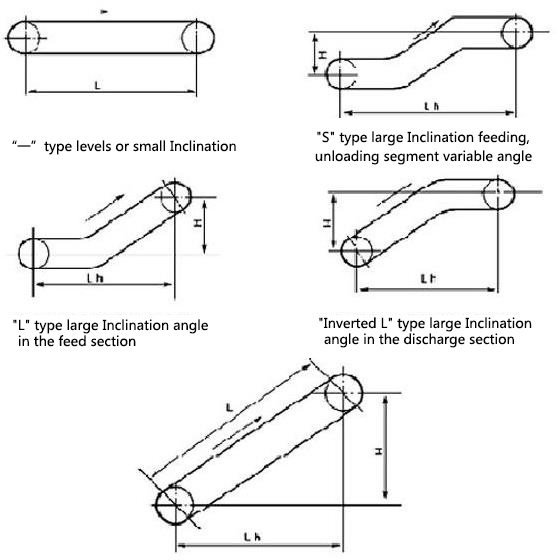

Machine layout:

In order to obtain better conditions by loading and unloading, the machine adopts "Z" shaped arrangement. That has a horizontal section, the horizontal section and inclined section, and the lower horizontal section that is expected, in the horizontal section of the discharge. Between the upper horizontal section and the inclined section of the convex arc segments connected to the frame, using the lower level between the inclined section and a concave arc segment chassis connected in order to achieve a smooth transition belt.

1, on the level segment: In order to meet the requirements of different heights unloading, headgear into low style headstock (headstock height H0 = 1000mm), Chinese headstock (headstock height H0 = 1100 ~ 1500mm) and high-style head stand (headstock height H0 = 1600 ~ 2000mm); and Correspondingly, the horizontal segment were equipped with low convex arcs racks and racks of low formula legs (equipped with a head frame height H0 = 1000mm), Chinese convex arcs racks and Chinese intermediate frame legs (equipped with a head frame height H0 = 1100 ~ 1500mm), high convex arcs high style chassis and the intermediate frame legs (equipped with a head frame height H0 = 1600 ~ 2000mm ) .

2. Tilt segment: Whether the use of a low-level segment, Chinese, or high-style in the middle frame leg, inclined section are low-type intermediate frame legs. When the conveyor angle β≥45 °, recommend the use of low-type intermediate frame legs.

3. The lower horizontal segment: lower horizontal segment with low-type intermediate frame legs.

Second, DJ-steep belt conveyor features:

1. saving footprint, saving investment.

2. throughput, versatility.

3. Conveyor inclination: 0 ° -90 °

4. easy maintenance, roller and other parts with ordinary conveyor.

5. Wide range of applications: metallurgy, mining, port, environmental protection, food, chemicals, building materials and so on.

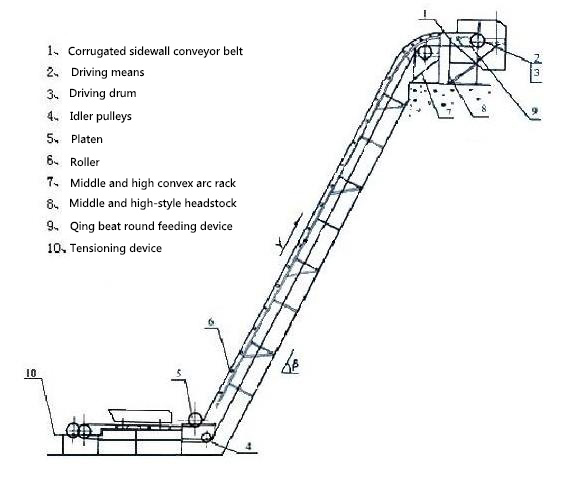

Third, DJ-steep belt conveyor structure diagram:

Fourth, DJ-steep belt conveyor member name and use:

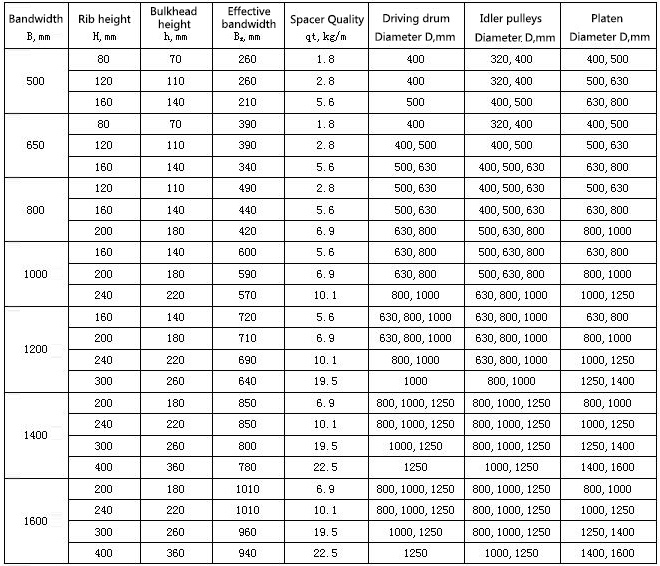

1. corrugated sidewall conveyor belt: from hoisting and carrying in conveyor. Corrugated wall, the crossbeam and baseband form a conveying material "gates" to describe the device, in order to achieve large transmission angle.

2. The driving device is the conveyor of the power section. Department of the Y series motor, ZJ type shaft-mounted reducer, wedge-type backstop components.

3. The drive pulley: is the main component of the power transmission, conveyor and run by the friction between the rollers with the drive. This series has a rubber surface drive roller and smooth points, rubber roller surface in order to increase the adhesion between the roller and the conveyor belt.

4. Idler pulleys: for changing the direction of the conveyor belt; bend drum for the lower surface of the conveyor belt (non-bearing surface).

5. platen: for changing the direction of the conveyor belt, the pressure on the belt pulley for the surface (bearing surface).

6. Roller: roller for supporting a conveyor belt and the belt material, stabilized operation. This series has a parallel roller, roller parallel under two types.

7. care tape roll: Entrusted with rollers for supporting the convex arcs rack conveyor lower branch, which is supported on both sides of the conveyor belt with an empty pail. Several groups of support with rollers form a circular arc segment for causing the conveyor belt redirection. Cantilever bracket with roller bearing.

8. vertical roll: vertical roller conveyor for limiting deviation, and is mounted on the lower section of the rack over. Each filter segment is provided on the frame 4, the upper and lower two points each.

9. flapping round clear material means: pat on the back for sticking on the belt conveyor fear of falling material.

10. The tensioning device acts:

1) With the conveyor belt has enough tension between the conveyor and the drive roller to ensure that does not slip.

2) Restrict the conveyor belt sag between each support, so the normal operation of the conveyor, the series spiral tensioning device.

11. rack, funnel head, head cover, guide trough, intermediate frame, the middle frame leg, etc: play supporting each conveyor, the dust and material guiding role.

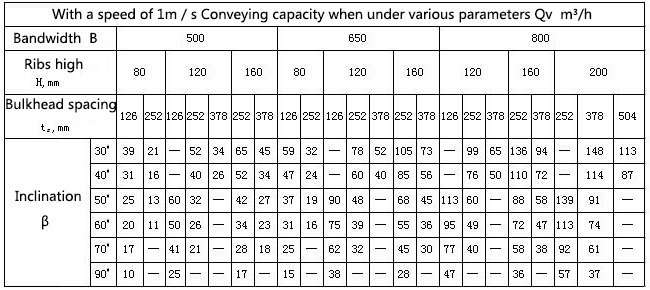

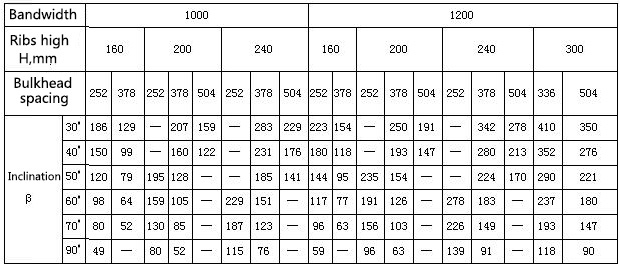

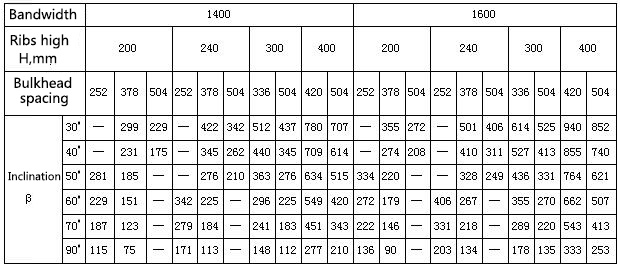

Fifth, DJ-steep belt conveyor technical parameters:

|