First, NE series board chain bucket elevator Overview:

NE series board chain bucket elevator for conveying powder, granular, small block abrasive or non-abrasive materials, such as raw materials, cement, coal, limestone, dry clay, clinker and so on, the material temperature controlled at 250 ℃. The series hoist use into the feeder, induction discharge; within material flowing into the hopper on board upgrade to the top of the chain, at its own gravity unloading materials. The main technical parameters in line with the Ministry of Machinery Standard (JB3926-85).NE plate chain bucket elevator is the introduction of foreign advanced technology and enhance the development of new products; the energy efficient, NE plate chain bucket elevator is gradually replace HL type bucket elevator. Chain of high-quality high-strength alloy steel plate chain, wear and reliable.Hardened reducer drive part.

Second, NE series board chain bucket elevator Features:

1, sealing, and less environmental pollution.

2, operation, easy maintenance, less wearing parts.

3, due to less energy-efficient and maintenance, low cost of ownership.

4, reliable, advanced design principles to ensure the reliability of machine operation, sealing, and less environmental pollution.

5, structural rigidity, high precision. After hemming and intermediate casing beading, and then by welding, good rigidity, beautiful appearance.

6, small mechanical dimensions, compared with the same amount of lift various other hoist, hoist machinery of this small size.

7, transmission capacity, this series hoist has NE15 ~ NE800 variety of specifications. Lift amount in the range of 15 ~ 800m3 / h. Loss, low noise, and long life.

Third, NE series board chain bucket elevator main structure and features:

NE series board chain bucket elevator by the moving parts, drives, upper unit, the central cabinet, the lower device component.

1, the upper unit: rail mounted (double track), to prevent the chain swinging backstop to prevent rotation of the hopper, the material blocking full lower housing, the discharge port is equipped with rubber plate to prevent back feed.

2, the middle section: the middle part of the section containing the track (double section) in order to prevent the chain swing work, part of the middle section is equipped with access doors for maintenance.

3, the lower part of the device: the installation of the tensioning device, NE15 ~ NE50 with spring tension, HNE100 ~ HNE800 box using heavy hammer tensioning.

4, the upper and lower sprocket ZG310-570. Overall quenching, HB229-269 tooth surface hardening

5, plate chain: chain plate using 45 # HRC36 ~ 42.

a, use of plate chain have higher shear strength, fatigue strength and wear resistance, running low failure rate, long service life;

b, a lower link speed (0.5 m / s);

c, using the hopper and smaller from large-capacity bucket, drive low power and transport capacity, particularly adapted to enhance the limestone and cement clinker crushed (≥NE50).

Fourth, NE series board chain bucket elevator characteristics and technical requirements:

1, taken into the feeder, conveyor so rarely occurs between the parts and materials as well as extrusion and collision, smooth operation, easy maintenance.

2, the conveyor chain using the contact panel, instead of the traditional bucket chain's point of access, thus improving service life, conveyor chain life up to five years.

3, due to take up into the feeder, gravity induction discharge, fighting low wire-speed high (15-30m / min), no material phenomenon back to power the equivalent of only about 40% of normal chain bucket machine.

4, the operation rate, trouble-free operation up to 30,000 hours.

5, delivery capability, while conveying the range 15-800m3 / h.

¤ alloy steel wear sleeve roller chain:

1, selected special steel production of high-quality materials, advanced heat treatment process.

1), the inner and outer link plates: 40Cr;

2), pin: 20CrMnMo;

3), sleeve: 20CrMo;

4), roller: 20CrMo; quenching HB293-365;

Carbon nitriding (0.5mm) quenching HRC55-62;

Carbon nitriding (0.5mm) quenching HRC55-60;

Carbon nitriding (0.5mm) quenching

2, Germany imported automatically flip Net bag heat treatment equipment, uniform and thorough case hardening.

1), pin and outer link plate is fixed, the sleeve and the inner chain plate fixation effectively reducing wear bearing member.

2), pin and sleeve, roller and sleeve to take a different clearance fit according to material and keep it on the chain wear and pitch elongation.

3), the outer link plates punched into curved plate structure fixed Douzi convenient, and reduce the use of space transportation agencies.

3, take the S & P seized and breaking tensile test detection means to fully guarantee the technical requirements.

¤ head sprocket:

1, structure: the wheels and split ring components.

2, Material: hub ZG45; 20CrMo forged steel ring gear; high-strength hinges straight bolt.

3, Technical data: points 12 teeth, two low-speed 24 teeth.

4, processing methods: synchronous overall machining line cutting; after installation division.

5, the heat treatment method: a hub quenching HB217-255; ring surface hardening hardness

¤ rear sprocket

1, Material: ZG35Mn.

2. Technical data: Nimbus toothless fine cars.

3. Heat treatment: IF quenching HRC55-60.

4, tail wheel light tooth can effectively prevent the head and tail are not synchronized jump teeth and cause wear and tear.

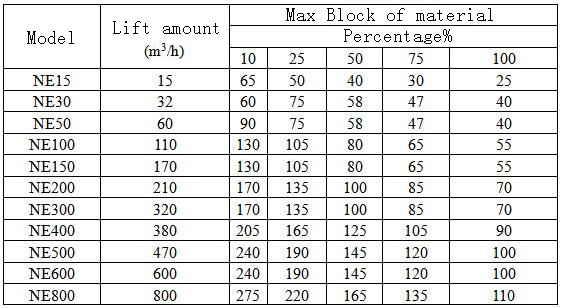

Fifth, NE series board chain bucket elevator technical parameters:

Sixth, NE plate chain bucket elevator installation dimensions:

Seventh, NE series board chain hoist according to package size and basic shape table:

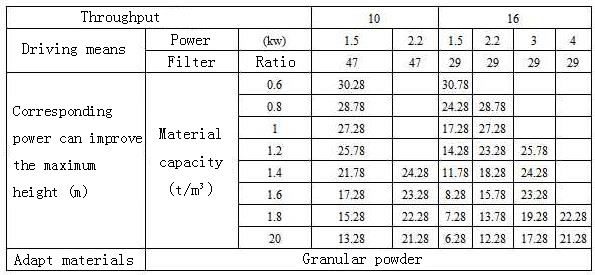

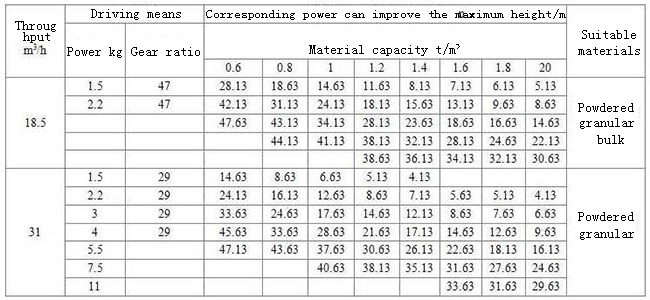

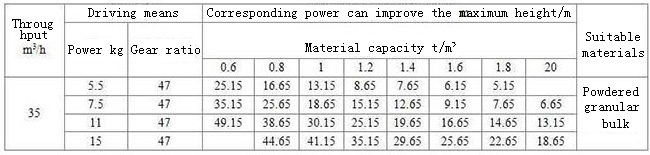

Powered hoist with:

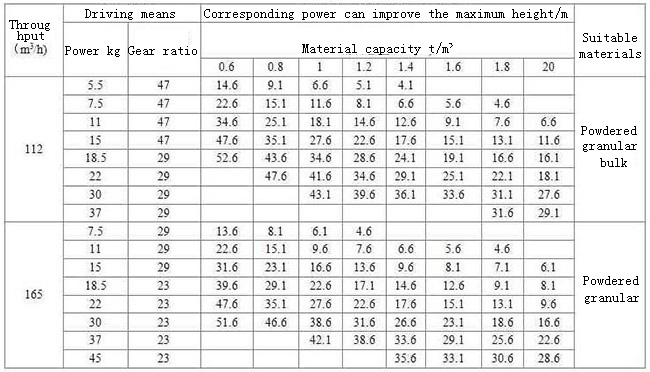

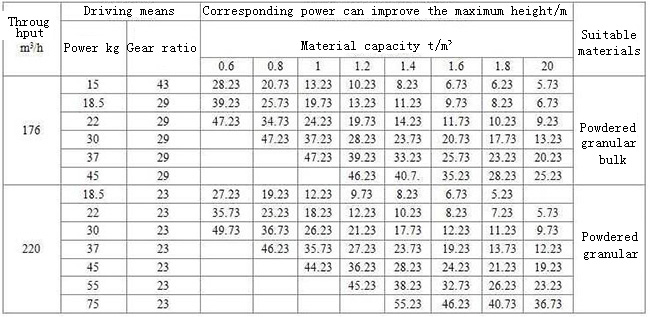

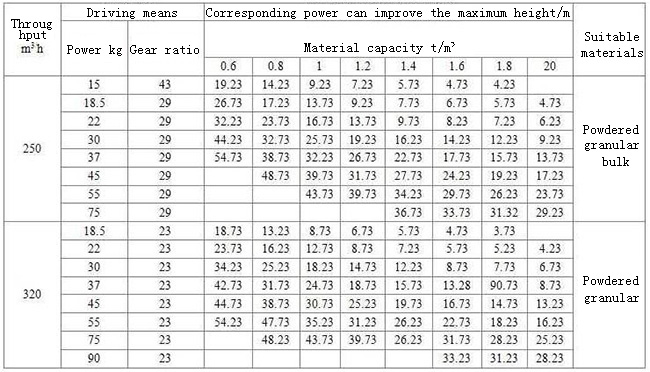

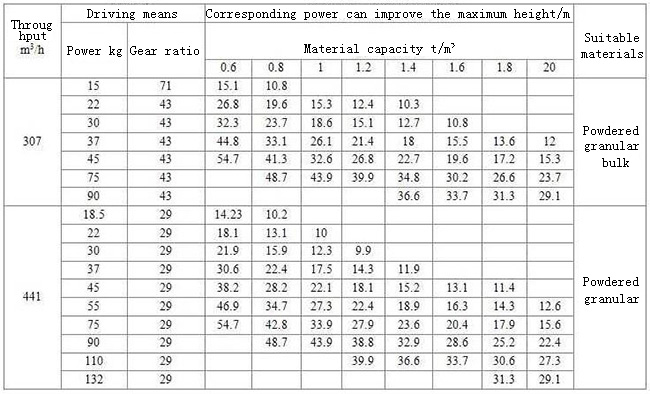

Maximum lift amount NE15, NE30, NE50, NE150, NE200, NE300, NE400 type hoist, Maximum lifting height and power equipment Table 1,2,3,4,5,6,7,8. Select the NE500, NE600, NE800 type when hoist, please contact our technical department.

Table 1 NE15 plate chain hoist drives and Maximum lifting height

Table 2 NE30 plate chain hoist drives and Maximum lifting height

Table 3 NE50 plate chain hoist drives and Maximum lifting height

Table 4 NE100 plate chain hoist drives and Maximum lifting height

Table 5 NE150 plate chain hoist drives and Maximum lifting height

Table 6 NE200 plate chain hoist drives and Maximum lifting height

Table 7 NE300 plate chain hoist drives and Maximum lifting height

Table 8NE400 plate chain hoist drives and Maximum lifting height

|