First, TD-type bucket elevator basic structure:

TD-type bucket elevator run by part (hopper with traction tape), the upper section with driving drum, the lower section with a tension roller, intermediate casing, drives, check brakes and other components. TD-type bucket elevator for transporting up loose density ρ <1.5t / m3 powder, granular and small block of non-abrasive and semi-abrasive bulk materials such as coal, sand, at the end of coke, cement, crushed ore.

Second, TD-type bucket elevator structure machine

There are two forms of transmission, each equipped with YZ reducer, ZQ (or YY) reducer. YZ-type shaft gear mounted directly on the spindle shaft head, eliminating the hoist drive platform, couplings, etc., to compact, light weight, and improve internal machine with a profiled roll backstop, backstop and reliable. The reducer, low noise, smooth operation, and with the spindle floating installation can eliminate stress.

Third, TD-type bucket elevator Features:

1, the driving power is small. Adoption into the feeder, induction discharge, large capacity hopper-intensive layout, material hoist when almost no feed back and excavating, therefore, less reactive power.

2, to enhance a wide range. Such hoist on the kind of materials, characteristics require less, not only to enhance the general powder, small granular materials, but also can improve the larger abrasive materials, sealing, and less environmental pollution.

3, reliable operation. Advanced design principles and processing methods to ensure the reliability of the machine running trouble-free time more than 20,000 hours. Lift and high lift machine run smoothly, so you can achieve a higher lifting height.

4, long service life. Hoist take inflow feeding formula, without using bucket digging materials, extrusion and collision between material rarely occurs. Designed to ensure that the material at the time of feeding, unloading few scattered, reducing mechanical wear.

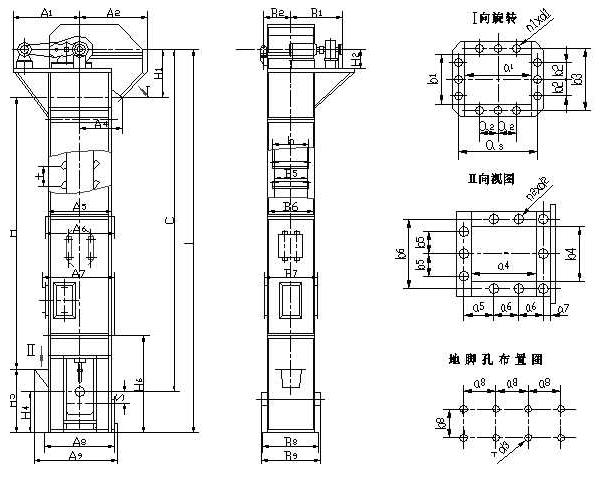

Fourth, TD-type bucket elevator installation dimensions:

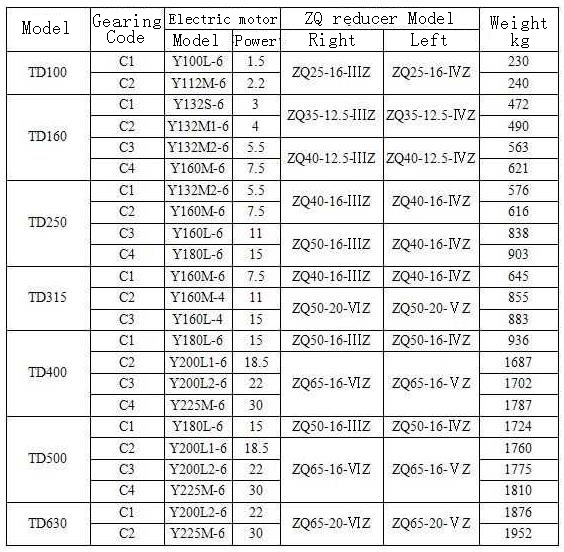

Fifth, TD-type bucket elevator drive is equipped with tables:

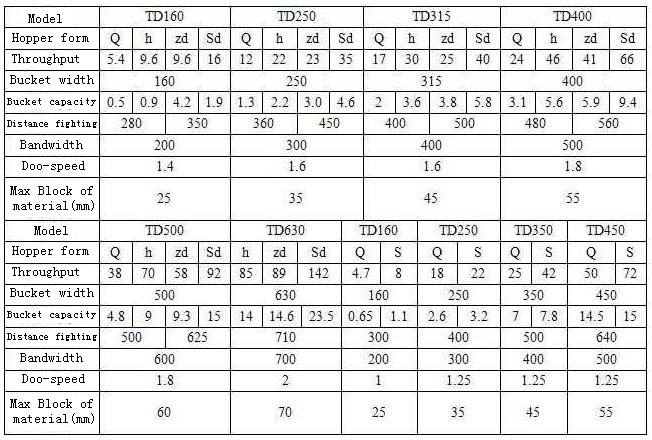

Sixth, TD-type bucket elevator machine technical parameters:

Comment:

1, the table is calculated bucket capacity bucket capacity, throughput is calculated according to the fill factor 0.6.

2, Hopper uses as:

Shallow Hopper: transport moist, easy to agglomerate, thrown hard materials. Such as wet sand, wet coal.

Deep hopper: transportation of dry, loose, easy thrown material. Such as cement, coal, gravel, quartz sand.

Each part of the lubrication cycle:

| No. |

Lubricating parts |

Lubricating materials |

Lubrication cycle |

Lubrication method |

|

1 |

Conveyor tension roller bearings |

Waterproof grease |

200 hours |

Use oiler |

|

2 |

Coupling backstop |

Waterproof grease |

50 hours |

Use oiler |

|

3 |

Tighten bolts |

Waterproof grease |

500 hours |

Smear |

|

4 |

Electric motor |

Waterproof grease |

6 months |

35 | |